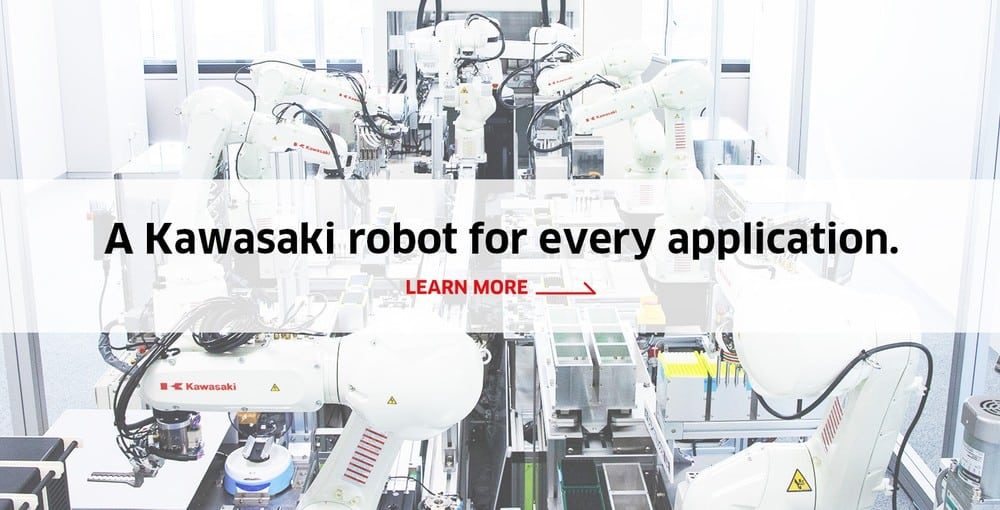

Why Kawasaki Robotics?

With a service-based approach, a flexible and open programming language and a manufacturer-first mindset, learn what makes us a different type of robot company.

Robot Automation FAQs

Browse these frequently asked robot automation questions and find answers straight from our experts. We are committed to your automation success and are happy to help anyway we can.

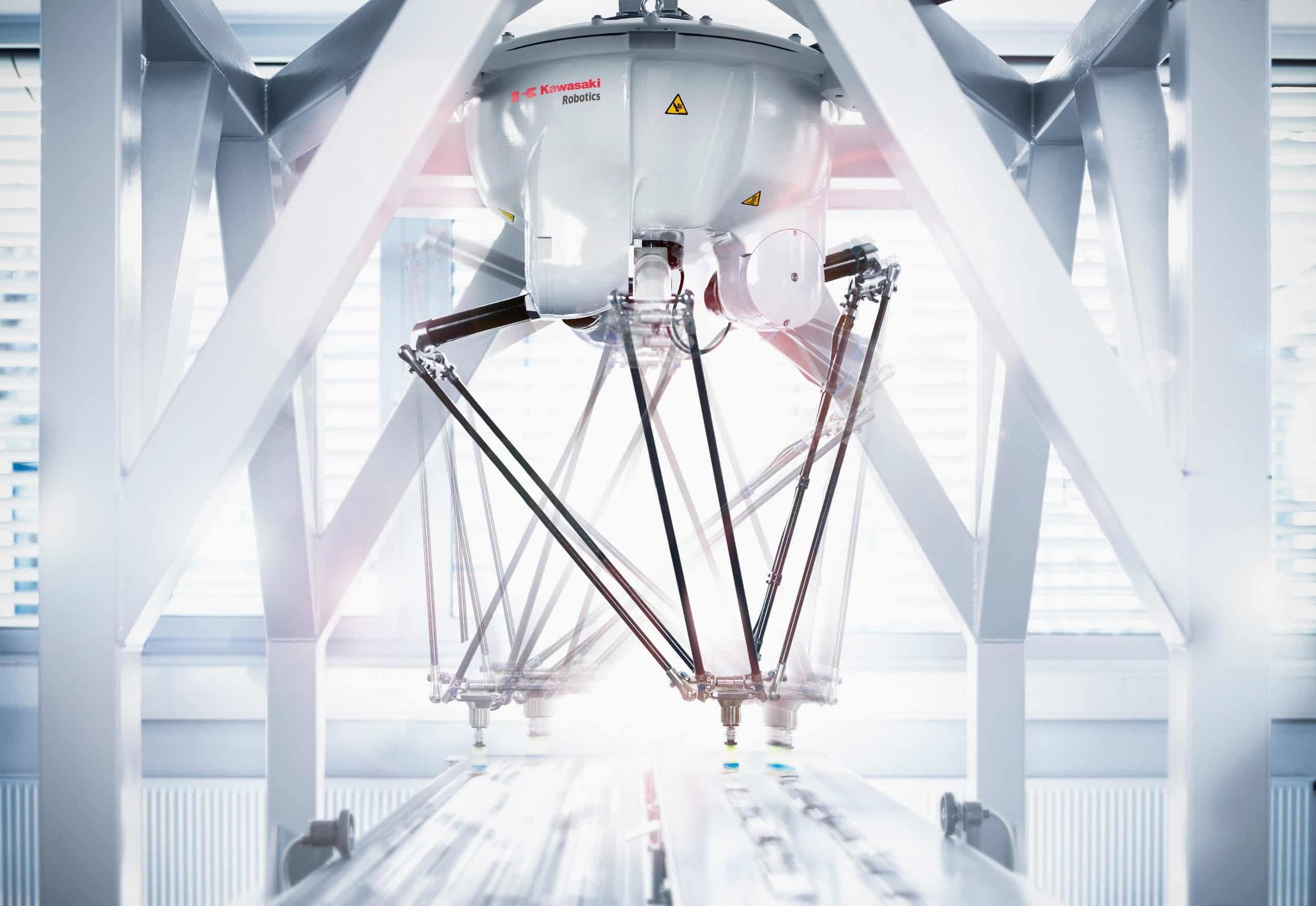

PRODUCTS

CASE STUDIES

EVENTS

CUSTOMER EXPERIENCE

NEWS

BLOG

Want to get started, or have question?

Our team is one click away.